Page 13 - Expresslab_E-Book

P. 13

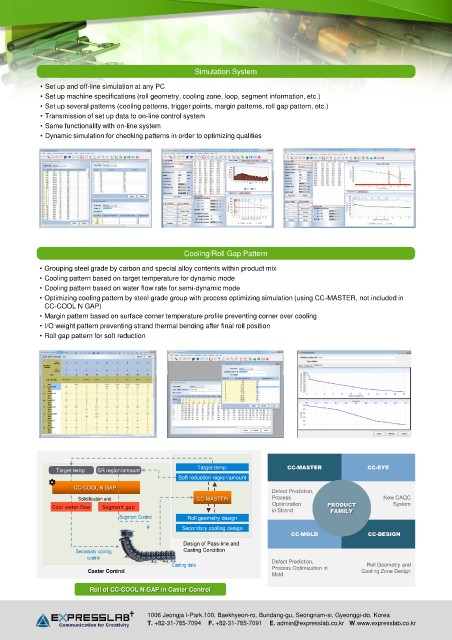

Simulation System

• Set up and off-line simulation at any PC

• Set up machine specifications (roll geometry, cooling zone, loop, segment information, etc.)

• Set up several patterns (cooling patterns, trigger points, margin patterns, roll gap pattern, etc.)

• Transmission of set up data to on-line control system

• Same functionality with on-line system

• Dynamic simulation for checking patterns in order to optimizing qualities

Cooling/Roll Gap Pattern

• Grouping steel grade by carbon and special alloy contents within product mix

• Cooling pattern based on target temperature for dynamic mode

• Cooling pattern based on water flow rate for semi-dynamic mode

• Optimizing cooling pattern by steel grade group with process optimizing simulation (using CC-MASTER, not included in

CC-COOL N GAP)

• Margin pattern based on surface corner temperature profile preventing corner over cooling

• I/O weight pattern preventing strand thermal bending after final roll position

• Roll gap pattern for soft reduction

Target temp. CC-MASTER CC-EYE

Target temp. SR region/amount

Soft reduction region/amount

CC-COOL N GAP

Defect Prediction,

Solidification end CC-MASTER Process New CAQC

Cool water flow Segment gap Optimization PRODUCT System

in Strand FAMILY

Segment Control Roll geometry design

Secondary cooling design

CC-MOLD CC-DESIGN

Design of Pass-line and

Secondary cooling Casting Condition

control Defect Prediction,

Casting data Roll Geometry and

Caster Control Process Optimization in Cooling Zone Design

Mold

Roll of CC-COOL N GAP in Caster Control

1006 Jeongja I-Park,100, Baekhyeon-ro, Bundang-gu, Seongnam-si, Gyeonggi-do, Korea

T. +82-31-785-7094 F. +82-31-785-7091 E. admin@expresslab.co.kr W.www.expresslab.co.kr