Page 14 - Expresslab_E-Book

P. 14

Advanced Strip Temperature Control System

ST-OPTIMIZER

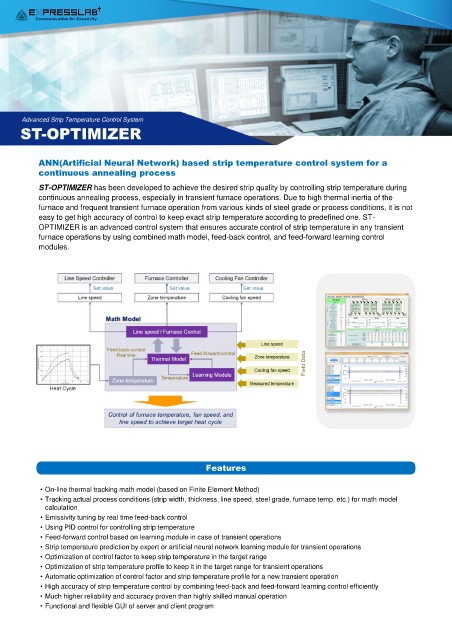

ANN(Artificial Neural Network) based strip temperature control system for a

continuous annealing process

ST-OPTIMIZER has been developed to achieve the desired strip quality by controlling strip temperature during

continuous annealing process, especially in transient furnace operations. Due to high thermal inertia of the

furnace and frequent transient furnace operation from various kinds of steel grade or process conditions, it is not

easy to get high accuracy of control to keep exact strip temperature according to predefined one. ST-

OPTIMIZER is an advanced control system that ensures accurate control of strip temperature in any transient

furnace operations by using combined math model, feed-back control, and feed-forward learning control

modules.

Features

• On-line thermal tracking math model (based on Finite Element Method)

• Tracking actual process conditions (strip width, thickness, line speed, steel grade, furnace temp. etc.) for math model

calculation

• Emissivity tuning by real time feed-back control

• Using PID control for controlling strip temperature

• Feed-forward control based on learning module in case of transient operations

• Strip temperature prediction by expert or artificial neural network learning module for transient operations

• Optimization of control factor to keep strip temperature in the target range

• Optimization of strip temperature profile to keep it in the target range for transient operations

• Automatic optimization of control factor and strip temperature profile for a new transient operation

• High accuracy of strip temperature control by combining feed-back and feed-forward learning control efficiently

• Much higher reliability and accuracy proven than highly skilled manual operation

• Functional and flexible GUI of server and client program