Page 9 - Expresslab_E-Book

P. 9

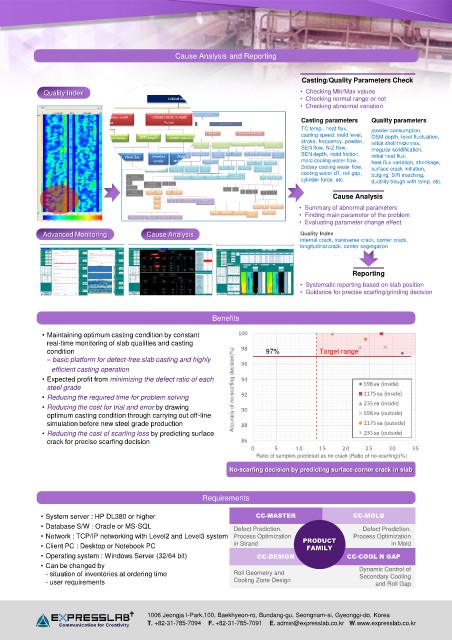

Cause Analysis and Reporting

Casting/Quality Parameters Check

Quality Index • Checking Min/Max values

• Checking normal range or not

• Checking abnormal variation

Transverse crack index

Casting parameters Quality parameters

Critical strain Applied strain

TC temp., heat flux, powder consumption,

Critical strain below mold Critical strain in mold OSM depth Irregular solidification(DI) casting speed, mold level,

ε cr,strand ε c,i,BTR OSM depth, level fluctuation,

stroke, frequency, powder,

Ductility Surface temp. BTR length Strain rate at S/L Negative strip Powder Initial shell thickness, d eff,i d eff,i Shell thickness initial shell thickness,

SEN flow, N/Z flow, irregular solidification,

trough,BTR time, t n consumption, Q s at mold exit, d eff,exit

Composition T L - T S ' Heat flux Friction Positive Fluidity index, I f Relative q i T L - T S ' q i T L - T S ' T L - T S ' Average SEN depth, mold friction,

(C,Si,Mn….) strain strip time, t p friction, F r heat flux initial heat flux,

2ndary cooling Dwell time, t m mold cooling water flow, heat flux variation, shrinkage,

k sys,i d cf T 0,i – T m,i

Initial Average Shell surface Flux melting Casting k sys,i d cf T 0,i – T m,i Powder 2ndary cooling water flow, surface crack initiation,

heat flux heat flux temp, T o temp, T m speed consumption, Q s cooling water dT, roll gap,

Powder

Interface Casting speed Viscosity frequency Stroke consumption,Q s k sys Q s d eff,i bulging, S/R matching,

conductivity, k sys cylinder force, etc.

d cf Interface Q s d eff,i ductility trough with temp. etc.

conductivity, k sys

T 0,i – T m,i

k 1200 T o

Powder I f t m F r

k 1200 T o q i T L - T S ' q i T L - T S '

consumption,Q s Cause Analysis

I f

k sys,i d cf T 0,i – T m,i Powder

t m

consumption,Q s

• Summary of abnormal parameters

F r k sys,i d cf T 0,i – T m,i

Stroke Viscosity frequency Casting T 0,i – T m,i

speed • Finding main parameter of the problem

Casting speed Viscosity frequency Stroke

• Evaluating parameter change effect

Advanced Monitoring Cause Analysis Quality Index

internal crack, transverse crack, corner crack,

longitudinal crack, center segregation

Reporting

• Systematic reporting based on slab position

• Guidance for precise scarfing/grinding decision

Benefits

• Maintaining optimum casting condition by constant 100

real-time monitoring of slab qualities and casting

condition 98 97% Target range

– basic platform for defect-free slab casting and highly 96

efficient casting operation

• Expected profit from minimizing the defect ratio of each 94

steel grade Accuracy of no-scarfing decision(%) 598 ea (inside)

• Reducing the required time for problem solving 92 1175 ea (inside)

• Reducing the cost for trial and error by drawing 90 235 ea (inside)

optimum casting condition through carrying out off-line 598 ea (outside)

simulation before new steel grade production 88 1175 ea (outside)

• Reducing the cost of scarfing loss by predicting surface 235 ea (outside)

crack for precise scarfing decision 86

0 5 10 15 20 25 30 35

Ratio of samples predicted as no crack (Ratio of no-scarfing)(%)

No-scarfing decision by predicting surface corner crack in slab

Requirements

• System server : HP DL380 or higher CC-MASTER CC-MOLD

• Database S/W : Oracle or MS-SQL Defect Prediction, Defect Prediction,

• Network : TCP/IP networking with Level2 and Level3 system Process Optimization PRODUCT Process Optimization

• Client PC : Desktop or Notebook PC in Strand FAMILY in Mold

• Operating system : Windows Server (32/64 bit) CC-DESIGN CC-COOL N GAP

• Can be changed by Dynamic Control of

- situation of inventories at ordering time Roll Geometry and Secondary Cooling

- user requirements Cooling Zone Design and Roll Gap

1006 Jeongja I-Park,100, Baekhyeon-ro, Bundang-gu, Seongnam-si, Gyeonggi-do, Korea

T. +82-31-785-7094 F. +82-31-785-7091 E. admin@expresslab.co.kr W.www.expresslab.co.kr