Page 12 - Expresslab_E-Book

P. 12

Advanced Simulating Software for Continuous Casting

CC-COOL N GAP

Dynamic control of secondary cooling and roll gap for continuous casting

CC-COOL N GAP was developed to control secondary cooling water flow and roll gap dynamically for continuous

casting based on predefined surface temperature profile. Dynamic secondary cooling and roll gap control is very

useful for obtaining good qualities of strand consistently. CC-COOL N GAP can be used for on-line control and off-

line simulation of secondary cooling and roll gap. Target surface temperature profiles included CC-COOL N GAP

are optimized for minimizing internal/surface crack of strand.

Features

• Using on-line thermal tracking model (based on Finite Element Method)

• Using actual casting conditions (casting speed, cooling water flows)

• Tunable model by user (provide open parameters for tuning of thermal model)

• Using both dynamic mode (target temperature base) and semi-dynamic mode (cooling water flow base)

• Using on/off margin control logic (modifying water flow by width of strand)

• Using movable spray margin control logic (modifying water flow by nozzle height determined by corner margin length)

• Tracking of steel grade, strand width, and cooling pattern

• Using PID control for maintaining surface temperature

• Using stabilizing logic for minimizing fluctuation of water flow (in case of casting start)

• Coupled with dynamic control of strand gap for soft reduction

• Supplying dynamic and semi-dynamic cooling pattern obtained by process optimization based on

qualities(internal/surface crack) of strand

• Flexible GUI (Customizing operating and monitoring GUI by user’s convenience)

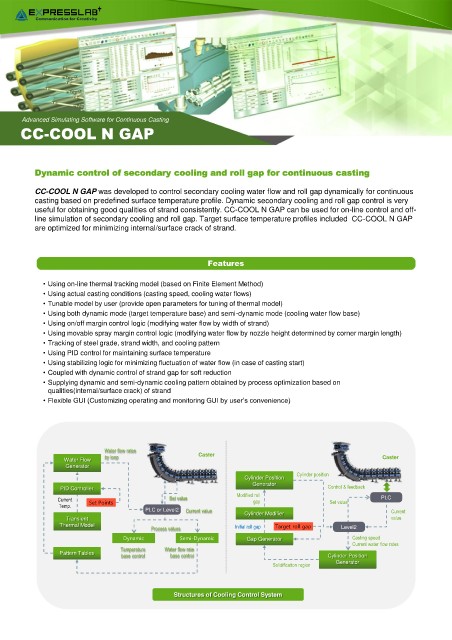

Water flow rates

by loop Caster Caster

Water Flow

Generator

Cylinder position

Cylinder Position

Generator

PID Controller Control & feedback

Modified roll

Current Set Points Set value gap Set value PLC

Temp.

PLC or Level2 Current value Cylinder Modifier Current

Transient value

Thermal Model Initial roll gap Target roll gap

Process values Level2

Dynamic Semi-Dynamic Gap Generator Casting speed

Current water flow rates

Temperature Water flow rate

Pattern Tables base control base control Cylinder Position

Generator

Solidification region

Structures of Cooling Control System