Page 15 - Expresslab_E-Book

P. 15

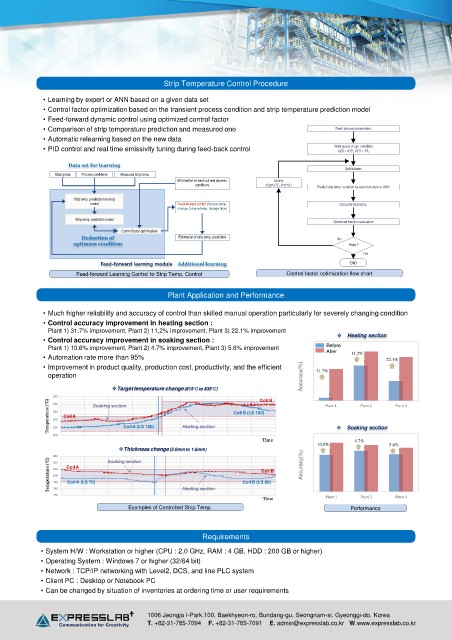

Strip Temperature Control Procedure

• Learning by expert or ANN based on a given data set

• Control factor optimization based on the transient process condition and strip temperature prediction model

• Feed-forward dynamic control using optimized control factor

• Comparison of strip temperature prediction and measured one Read process parameters

• Automatic relearning based on the new data

• PID control and real time emissivity tuning during feed-back control Initial guess of opt. variables

X(0) = dTF i , X(1) = S1 i

Data set for learning

Set features

Steel grade Process conditions Measured strip temp.

Information on next coil and process Modify

conditions X(0)=dTF, X(1)=S1

Predict strip temp. variation by expert module or ANN

Strip temp. prediction learning

model Feed-forward control (furnace temp. Calculate strip temp.

change, furnace temp. change time)

Strip temp. prediction model

Optimized function evaluation

Control factor optimization

Deduction of Estimation of strip temp. prediction No

optimum condition Fmin ?

Yes

Feed-forward learning module Additional learning END

Feed-forward Learning Control to Strip Temp. Control Control factor optimization flow chart

Plant Application and Performance

• Much higher reliability and accuracy of control than skilled manual operation particularly for severely changing condition

• Control accuracy improvement in heating section :

Plant 1) 31.7% improvement, Plant 2) 11,2% improvement, Plant 3) 22.1% improvement

• Control accuracy improvement in soaking section : 100 Heating section

Plant 1) 10.6% improvement, Plant 2) 4.7% improvement, Plant 3) 5.6% improvement Before 93.3

After 11.2% 89.5

• Automation rate more than 95% 90 83.9 22.1%

• Improvement in product quality, production cost, productivity, and the efficient 31.7% 81.52

operation Accuracy(%) 80 73.3

Target temperature change (815℃ to 835℃) 70

61.91

850 Soaking section Coil B 60

Temperature (℃) 830 Coil A Coil A (LS 150) Heating section Coil B (LS 150) Plant 1 Plant 2 Plant 3

840

820

810

800 Soaking section

Time 100 97.69 4.7% 95.8

10.6% 5.6% 93.8

Thickness change (2.0mm to 1.6mm) 88.36 91.5 88.8

830 Soaking section Accuracy(%) 90

Temperature (℃) 810 Coil A Coil B (LS 80) 80

820

Coil B

800

70

Coil A (LS 70)

790

780

770 Heating section 60 Plant 1 Plant 2 Plant 3

Time

Examples of Controlled Strip Temp. Performance

Requirements

• System H/W : Workstation or higher (CPU : 2.0 GHz, RAM : 4 GB, HDD : 200 GB or higher)

• Operating System : Windows 7 or higher (32/64 bit)

• Network : TCP/IP networking with Level2, DCS, and line PLC system

• Client PC : Desktop or Notebook PC

• Can be changed by situation of inventories at ordering time or user requirements

1006 Jeongja I-Park,100, Baekhyeon-ro, Bundang-gu, Seongnam-si, Gyeonggi-do, Korea

T. +82-31-785-7094 F. +82-31-785-7091 E. admin@expresslab.co.kr W.www.expresslab.co.kr