Page 8 - Expresslab_E-Book

P. 8

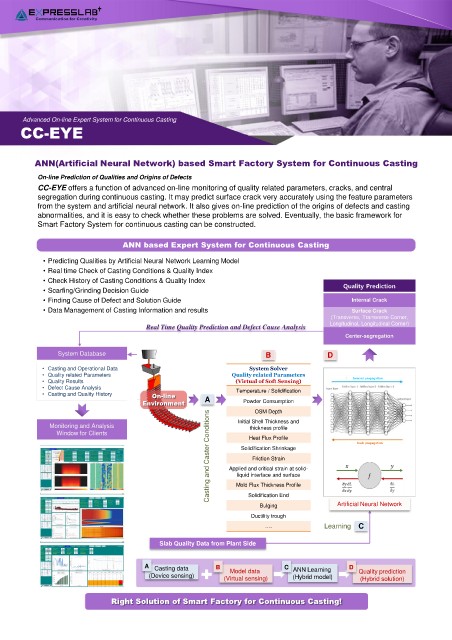

Advanced On-line Expert System for Continuous Casting

CC-EYE

ANN(Artificial Neural Network) based Smart Factory System for Continuous Casting

On-line Prediction of Qualities and Origins of Defects

CC-EYE offers a function of advanced on-line monitoring of quality related parameters, cracks, and central

segregation during continuous casting. It may predict surface crack very accurately using the feature parameters

from the system and artificial neural network. It also gives on-line prediction of the origins of defects and casting

abnormalities, and it is easy to check whether these problems are solved. Eventually, the basic framework for

Smart Factory System for continuous casting can be constructed.

ANN based Expert System for Continuous Casting

• Predicting Qualities by Artificial Neural Network Learning Model

• Real time Check of Casting Conditions & Quality Index

• Check History of Casting Conditions & Quality Index

• Scarfing/Grinding Decision Guide Quality Prediction

• Finding Cause of Defect and Solution Guide Internal Crack

• Data Management of Casting Information and results Surface Crack

(Transverse, Transverse Corner,

Real Time Quality Prediction and Defect Cause Analysis Longitudinal, Longitudinal Corner)

Center-segregation

System Database B D

• Casting and Operational Data System Solver

• Quality related Parameters Quality related Parameters forward propagation

• Quality Results (Virtual of Soft Sensing)

• Defect Cause Analysis Temperature / Solidification

• Casting and Quality History On-line

Environment A Powder Consumption

Casting and Caster Conditions Applied and critical strain at solid-

OSM Depth

Monitoring and Analysis Initial Shell Thickness and

thickness profile

Window for Clients Heat Flux Profile back propagation

Solidification Shrinkage

Friction Strain

liquid interface and surface

Mold Flux Thickness Profile

Solidification End

Bulging Artificial Neural Network

Ductility trough

…. Learning C

Slab Quality Data from Plant Side

A Casting data B C ANN Learning D

Model data

(Device sensing) (Virtual sensing) (Hybrid model) Quality prediction

(Hybrid solution)

Right Solution of Smart Factory for Continuous Casting!