Software for Continuous Casting

Professional Tool for Process Design, Process Optimization and Quality Estimation in Continuous Casting Mold

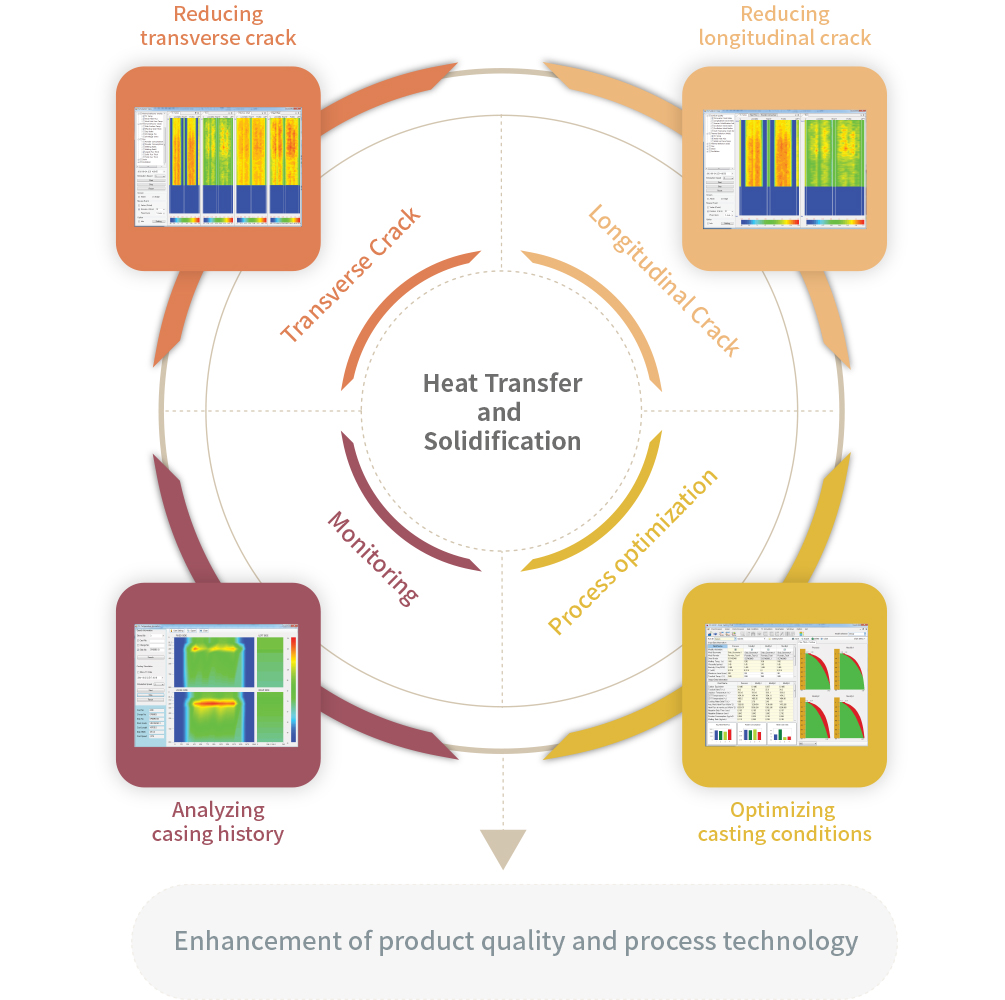

CC-MOLD is the professional tool developed for the process evaluation and optimization of continuous casting mold.

On/off-line system based on real data enables realistic and accurate simulation of continuous-casting process and defect evaluation of slabs in mold. Its flexible and powerful graphical user interface makes preparation of input data and examination of result data easy to accomplish.

Easy-to-Use / Competitiveness / User-friendly environment

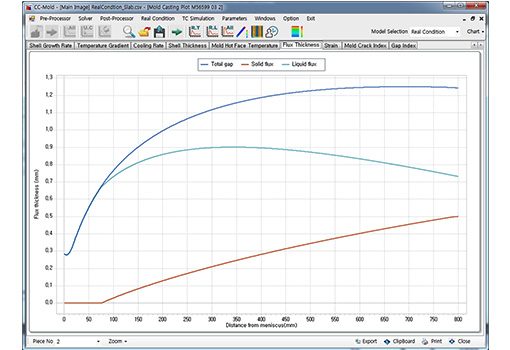

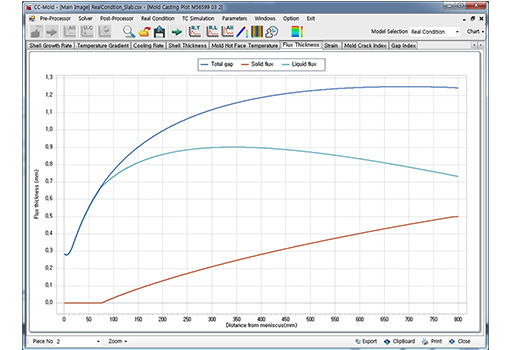

Compact Mold Module

Compact Mold Module enables to predict the temperature/solidification behaviors in mold with unique and simple model. This works in coordination with other modules.

Fast analysis of temperature and solidification behavior of solidified shellCalculation of effective shell thickness by micro-segregation analysis

Calculation of thermal shrinkage considering phase change with temperature

Evaluation of liquid flux thickness and powder consumption

Evaluation of oscillation mark depth and irregular solidification

Transverse Crack Module

Transverse Crack Module enables to evaluate the transverse and network intergranular crack index in mold. Prediction of crack initiation is very important for suppressing cracks because once crack is initiated, it readily propagates.

Calculation of applied strain and critical strain near meniscusReliable critical strain model at oscillation mark

Evaluation of friction strain near meniscus considering powder consumption

Estimation of crack propagation due to taper condition

Evaluation of transverse crack index in mold region

Evaluation of network intergranular crack index

Longitudinal Crack Module

Longitudinal Crack Module enables to evaluate the longitudinal crack index in mold. Uneven solidification is evaluated using temperature of Cu plate measured with thermo-couple.

Calculation of applied strain and critical strain near meniscusReliable critical strain model at depression Site

Applied strain due to thermal strain near meniscus

Estimation of crack propagation due to taper condition

Evaluation of longitudinal crack index

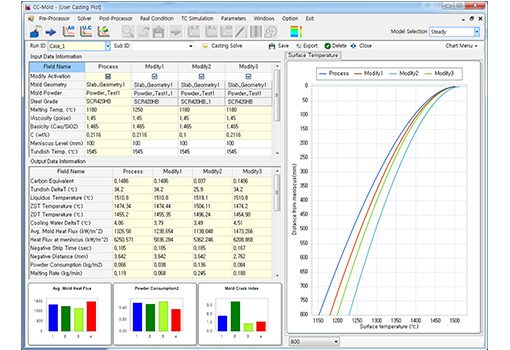

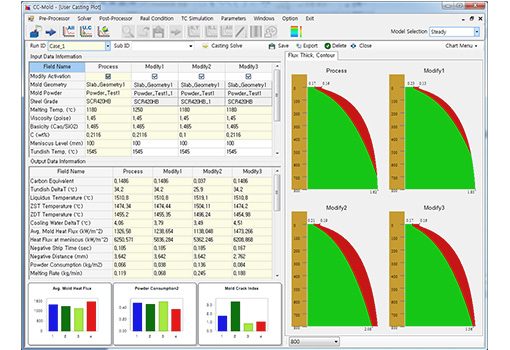

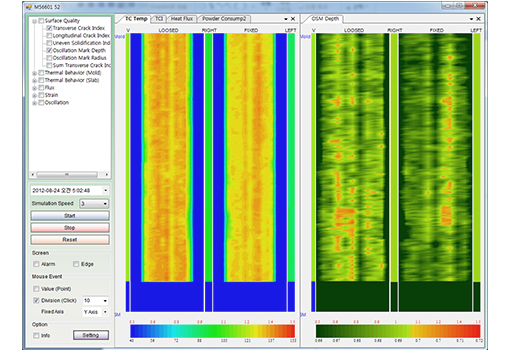

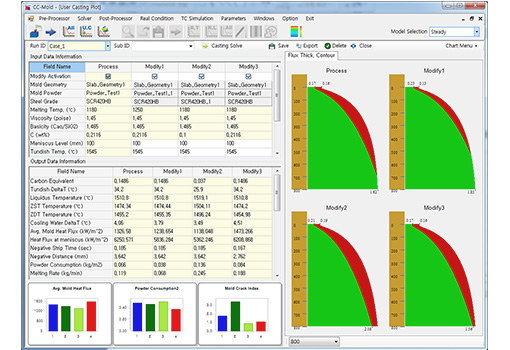

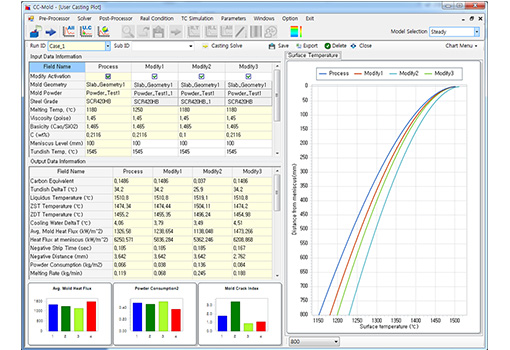

Process Simulation Module

Process Simulation Module enables to optimize process condition such as mold powder, oscillation pattern, cooling condition, etc. Set-up of casting condition for new steel grade can be established using this function efficiently.

Process optimization using simulator by changing parametersFinding proper process condition and applying it to real casting

Evaluation of process condition by comparing prediction with plant data

Easy-to-use interface for comparing changed conditions to each other

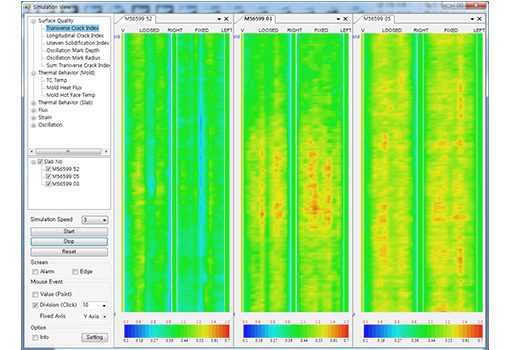

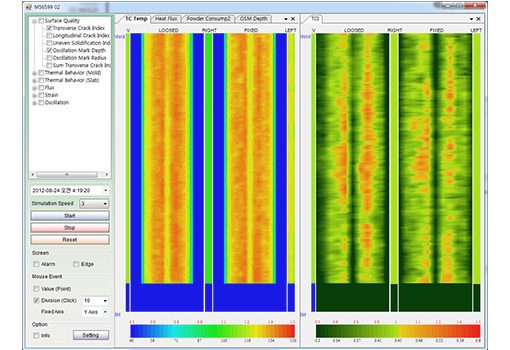

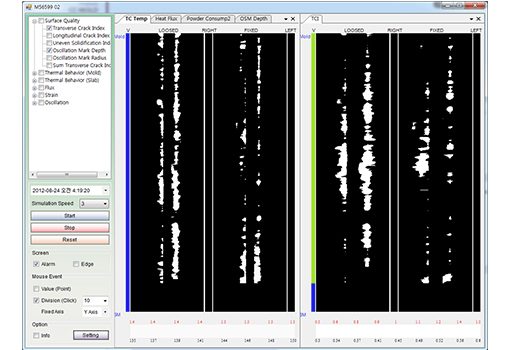

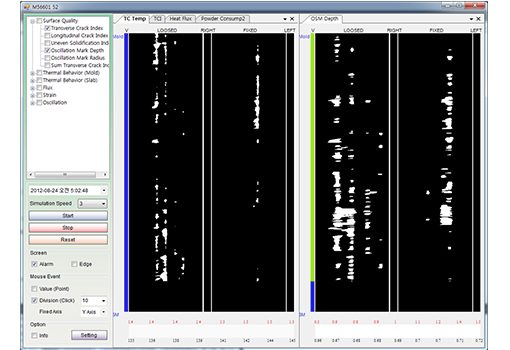

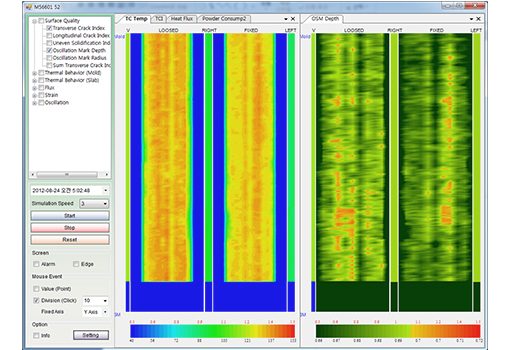

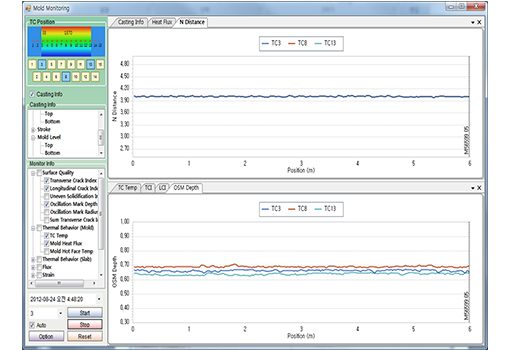

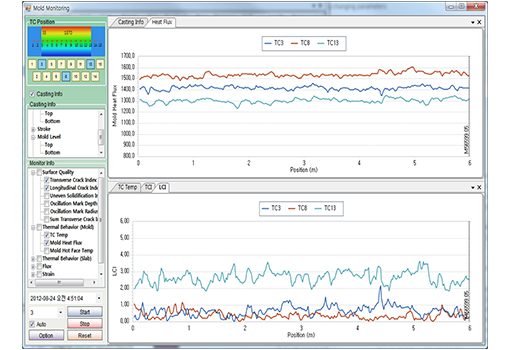

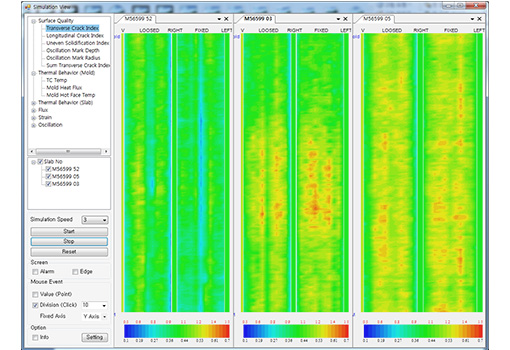

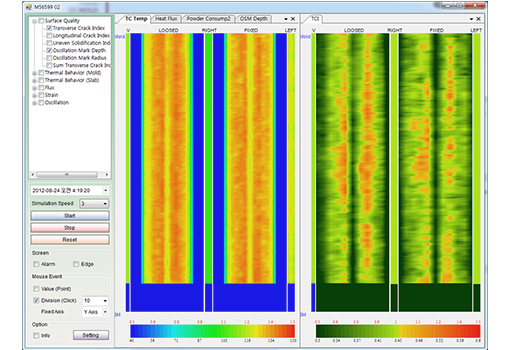

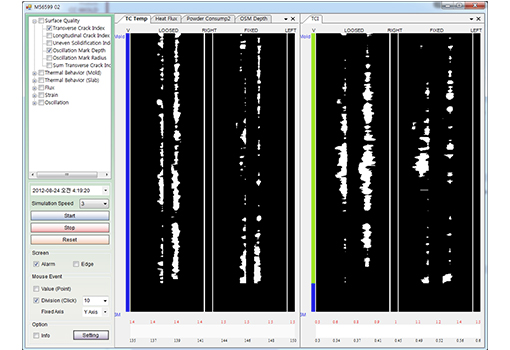

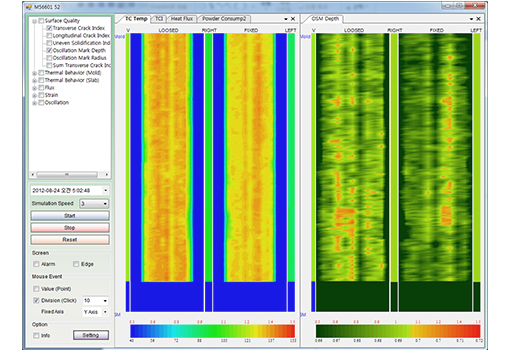

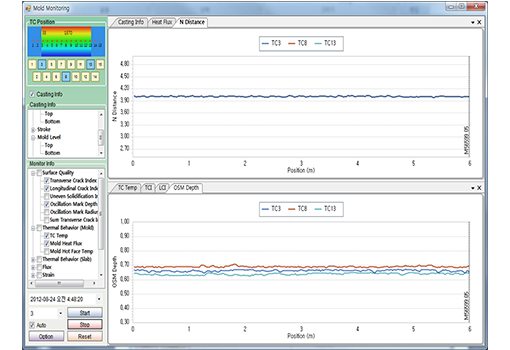

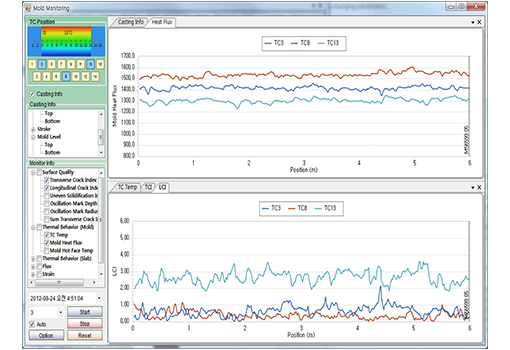

Monitoring Module

Monitoring Module enables to visualize casting conditions non-real-time. User can see casting history and calculated results by graphs and contour maps for checking the main factor of abnormal casting results.

Simulating casting conditions with saved plant data (on/off-line)Casting parameters (casting speed, cooling water amount, oscillating stroke/frequency, measured temperature, etc)

Calculated results (oscillation mark depth, powder consumption, crack index, etc)

Advanced simulating

Software for Continuous Casting

CC-MOLD

Catalog DownloadProfessional Tool for Process Design, Process Optimization and Quality Estimation in Continuous Casting Mold

CC-MOLD is the professional tool developed for the process evaluation and optimization of continuous casting mold.

On/off-line system based on real data enables realistic and accurate simulation of continuous-casting process and defect evaluation of slabs in mold. Its flexible and powerful graphical user interface makes preparation of input data and examination of result data easy to accomplish.

Easy-to-Use / Competitiveness / User-friendly environment

Compact Mold Module

Compact Mold Module enables to predict the temperature/solidification behaviors in mold with unique and simple model. This works in coordination with other modules.

Fast analysis of temperature and solidification behavior of solidified shellCalculation of effective shell thickness by micro-segregation analysis

Calculation of thermal shrinkage considering phase change with temperature

Evaluation of liquid flux thickness and powder consumption

Evaluation of oscillation mark depth and irregular solidification

Transverse Crack Module

Transverse Crack Module enables to evaluate the transverse and network intergranular crack index in mold. Prediction of crack initiation is very important for suppressing cracks because once crack is initiated, it readily propagates.

Calculation of applied strain and critical strain near meniscusReliable critical strain model at oscillation mark

Evaluation of friction strain near meniscus considering powder consumption

Estimation of crack propagation due to taper condition

Evaluation of transverse crack index in mold region

Evaluation of network intergranular crack index

Longitudinal Crack Module

Longitudinal Crack Module enables to evaluate the longitudinal crack index in mold. Uneven solidification is evaluated using temperature of Cu plate measured with thermo-couple.

Calculation of applied strain and critical strain near meniscusReliable critical strain model at depression Site

Applied strain due to thermal strain near meniscus

Estimation of crack propagation due to taper condition

Evaluation of longitudinal crack index

Process Simulation Module

Process Simulation Module enables to optimize process condition such as mold powder, oscillation pattern, cooling condition, etc. Set-up of casting condition for new steel grade can be established using this function efficiently.

Process optimization using simulator by changing parametersFinding proper process condition and applying it to real casting

Evaluation of process condition by comparing prediction with plant data

Easy-to-use interface for comparing changed conditions to each other

Monitoring Module

Monitoring Module enables to visualize casting conditions non-real-time. User can see casting history and calculated results by graphs and contour maps for checking the main factor of abnormal casting results.

Simulating casting conditions with saved plant data (on/off-line)Casting parameters (casting speed, cooling water amount, oscillating stroke/frequency, measured temperature, etc)

Calculated results (oscillation mark depth, powder consumption, crack index, etc)