Software for Continuous Casting

The Right Tool for Caster Pass-line Design

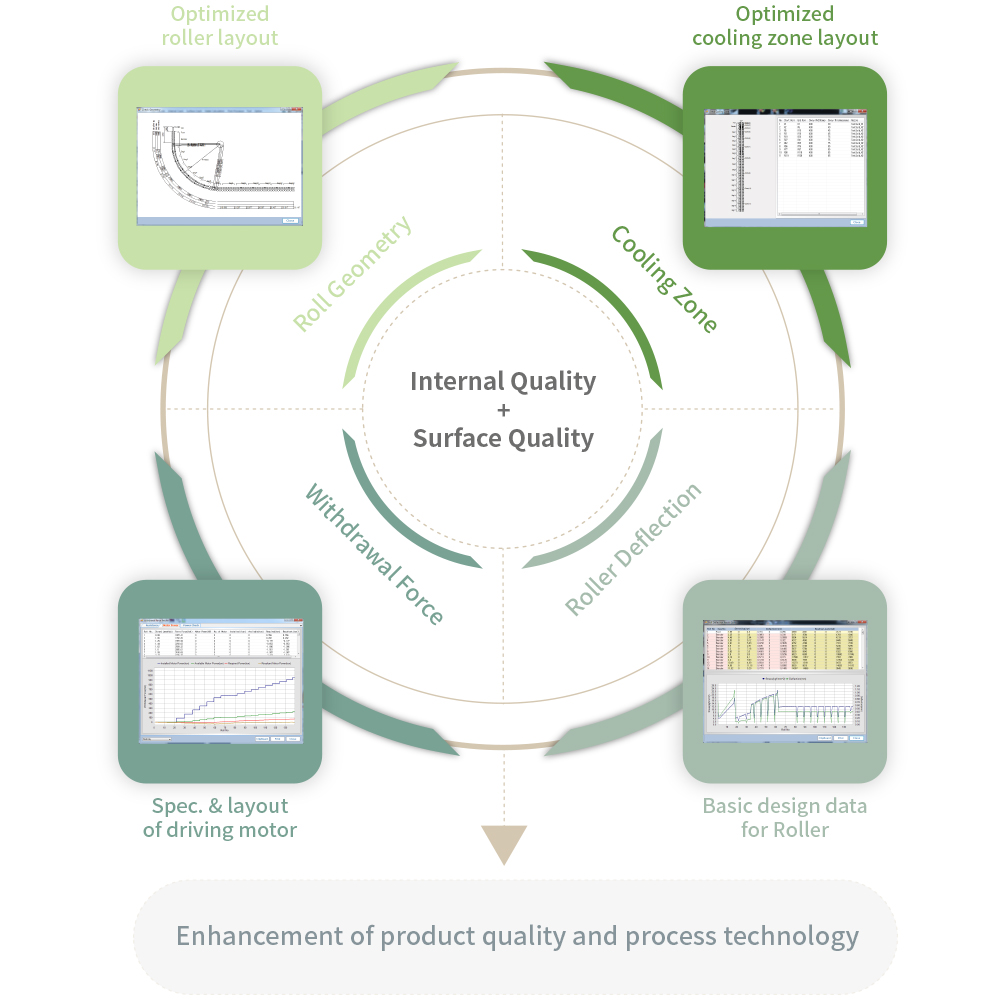

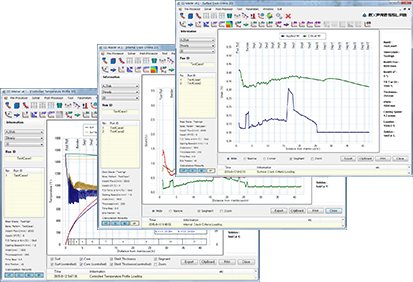

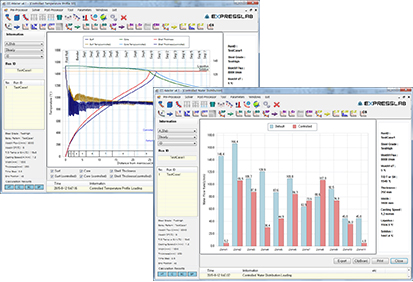

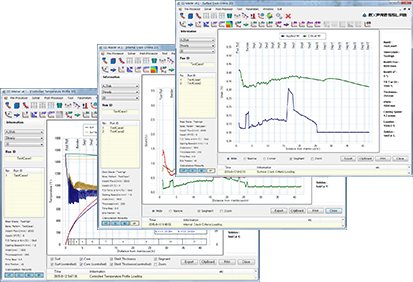

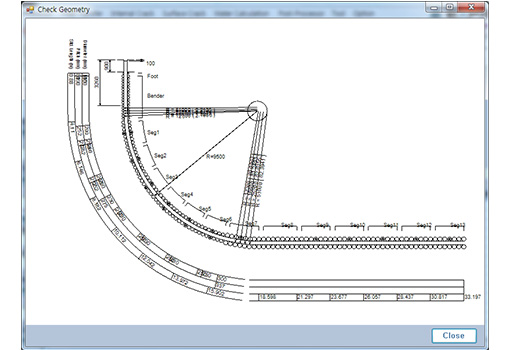

CC-DESIGN coupled with CC-MASTER solver was developed to design roll geometry of pass-line under which internal and surface cracks are prevented.

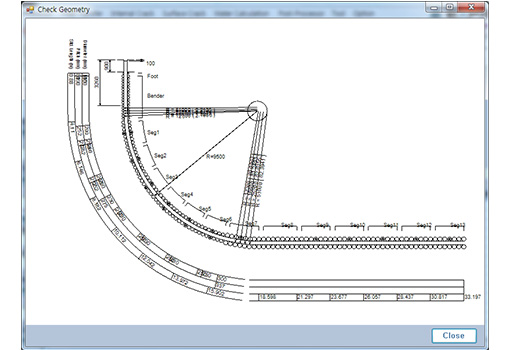

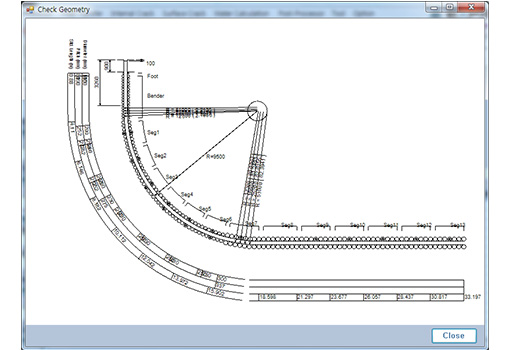

Therefore, CC-DESIGN can be used to check and feasibility of roll geometry and to edit the geometry. By checking the feasibility of achievement of target productivity with certain product-mix without internal cracks and surface cracks, roll geometry or segment can be designed or modified accordingly.

Easy-to-Use / Competitiveness / User-friendly environment

Features

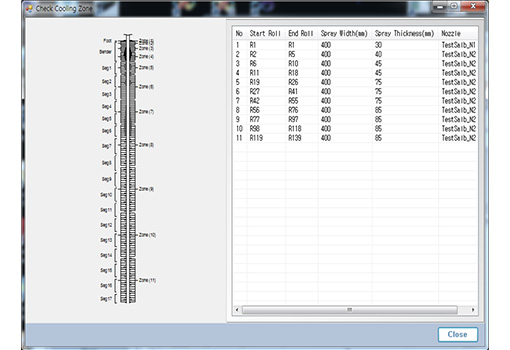

Roll geometry and cooling zone designCoupled with process simulator (CC-MASTER)

Roll geometry design or modification to prevent midway and transverse cracks

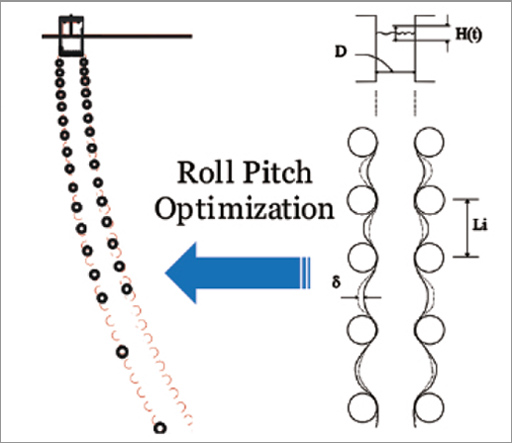

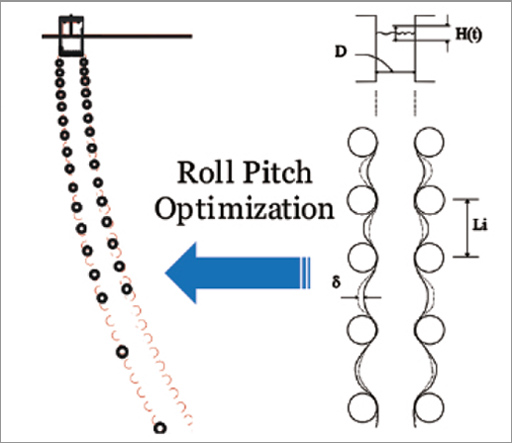

Roll pitch modification to reduce mold level fluctuation due to dynamic bulging

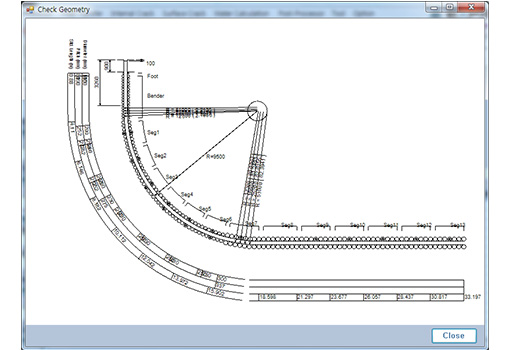

Checking the feasibility of and editing a roll geometry

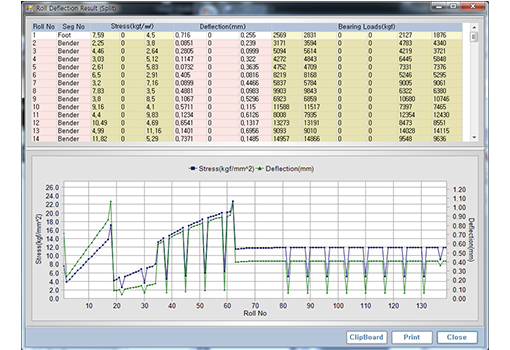

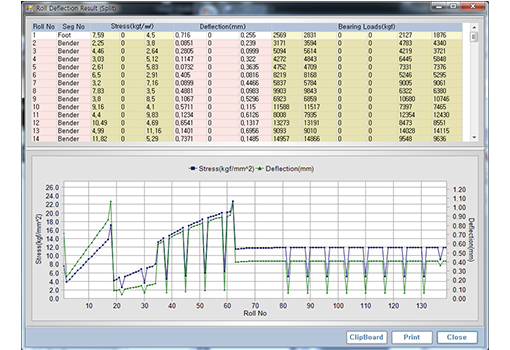

Useful results for roll and bearing design

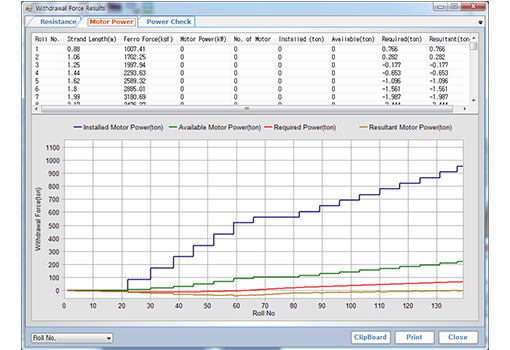

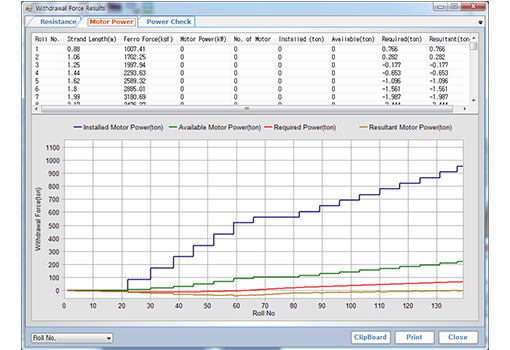

Useful results for choice of driving motor and layout of driving rolls

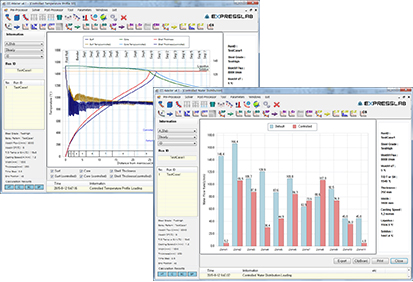

Stain Analysis to Prevent Cracking

Target Surface Temperature

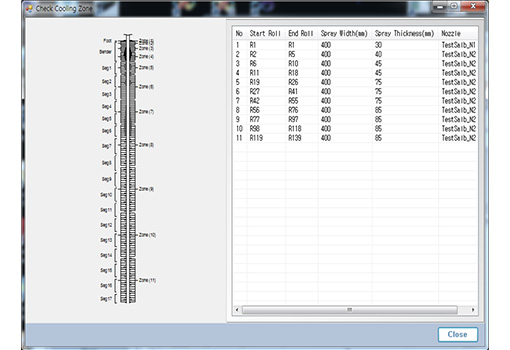

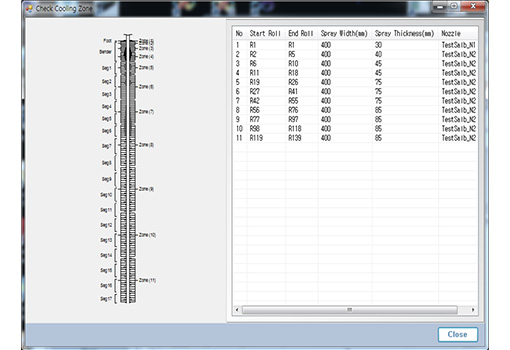

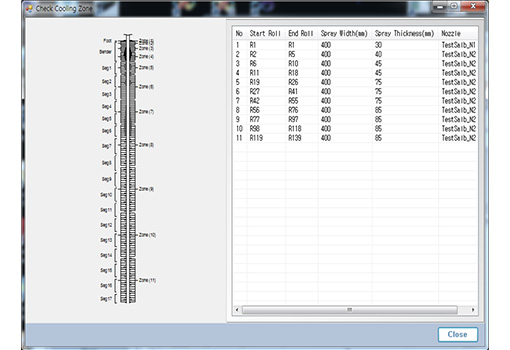

Cooling Zone Design

Modules

Basic module

Heat Transfer Module

Water Flux Calculation Module

User Interface

Additional module

Internal Crack Module

Surface Crack Module

Dynamic Bulging Module

Design Toolkit

Material Database

Thermal Properties DB

Internal Crack Properties DB

Surface Crack Properties DB

Functions

Autocad Script Export of Roll Geometry Data

Calculation of Roll Deflection by Split Type

Calculation of Bearing Loads

Calculation of Driving Motor Power

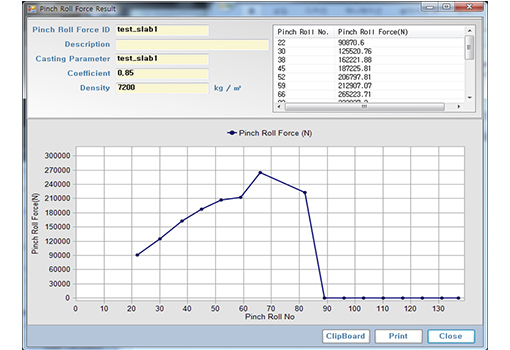

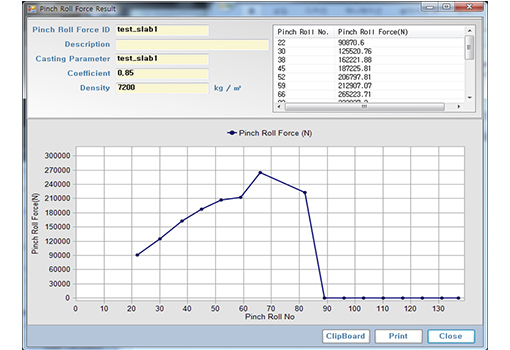

Calculation of Pinch Roll Force

Calculation of Soft Reduction Force

Advanced simulating

Software for Continuous Casting

CC-DESIGN

Catalog Download

The Right Tool for Caster Pass-line Design

CC-DESIGN coupled with CC-MASTER solver was developed to design roll geometry of pass-line under which internal and surface cracks are prevented.

Therefore, CC-DESIGN can be used to check and feasibility of roll geometry and to edit the geometry. By checking the feasibility of achievement of target productivity with certain product-mix without internal cracks and surface cracks, roll geometry or segment can be designed or modified accordingly.

Easy-to-Use / Competitiveness / User-friendly environment

Features

Roll geometry and cooling zone designCoupled with process simulator (CC-MASTER)

Roll geometry design or modification to prevent midway and transverse cracks

Roll pitch modification to reduce mold level fluctuation due to dynamic bulging

Checking the feasibility of and editing a roll geometry

Useful results for roll and bearing design

Useful results for choice of driving motor and layout of driving rolls

Stain Analysis to Prevent Cracking

Target Surface Temperature

Cooling Zone Design

Modules

Basic module

Heat Transfer Module

Water Flux Calculation Module

User Interface

Additional module

Internal Crack Module

Surface Crack Module

Dynamic Bulging Module

Design Toolkit

Material Database

Thermal Properties DB

Internal Crack Properties DB

Surface Crack Properties DB

Functions

Autocad Script Export of Roll Geometry Data

Calculation of Roll Deflection by Split Type

Calculation of Bearing Loads

Calculation of Driving Motor Power

Calculation of Pinch Roll Force

Calculation of Soft Reduction Force