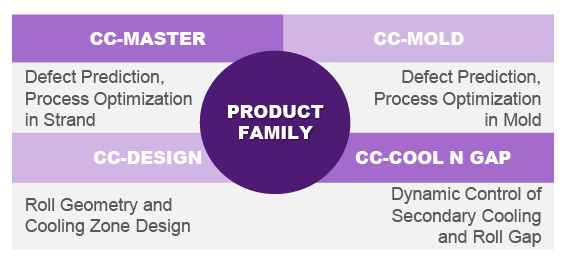

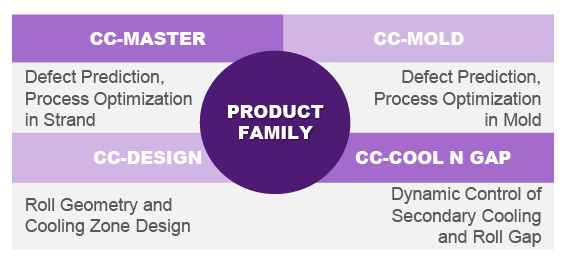

Software for Continuous Casting

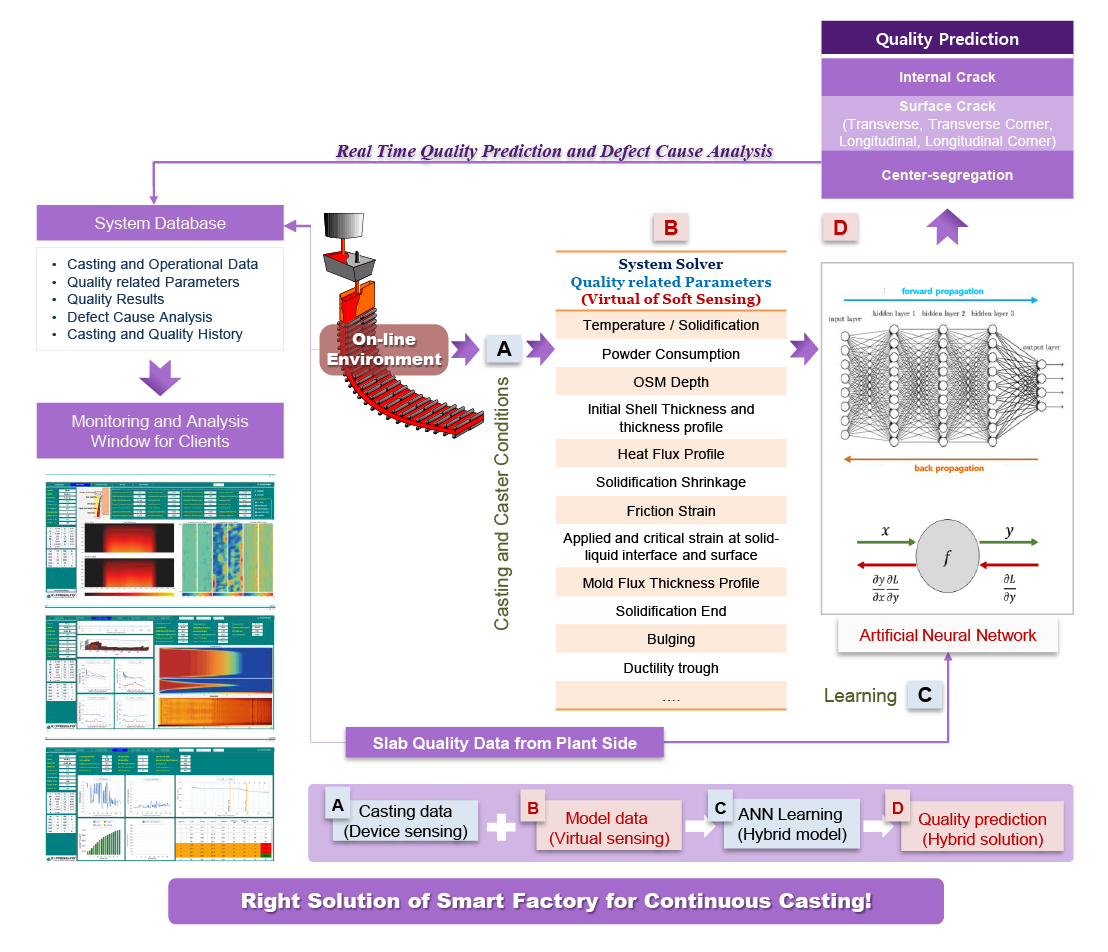

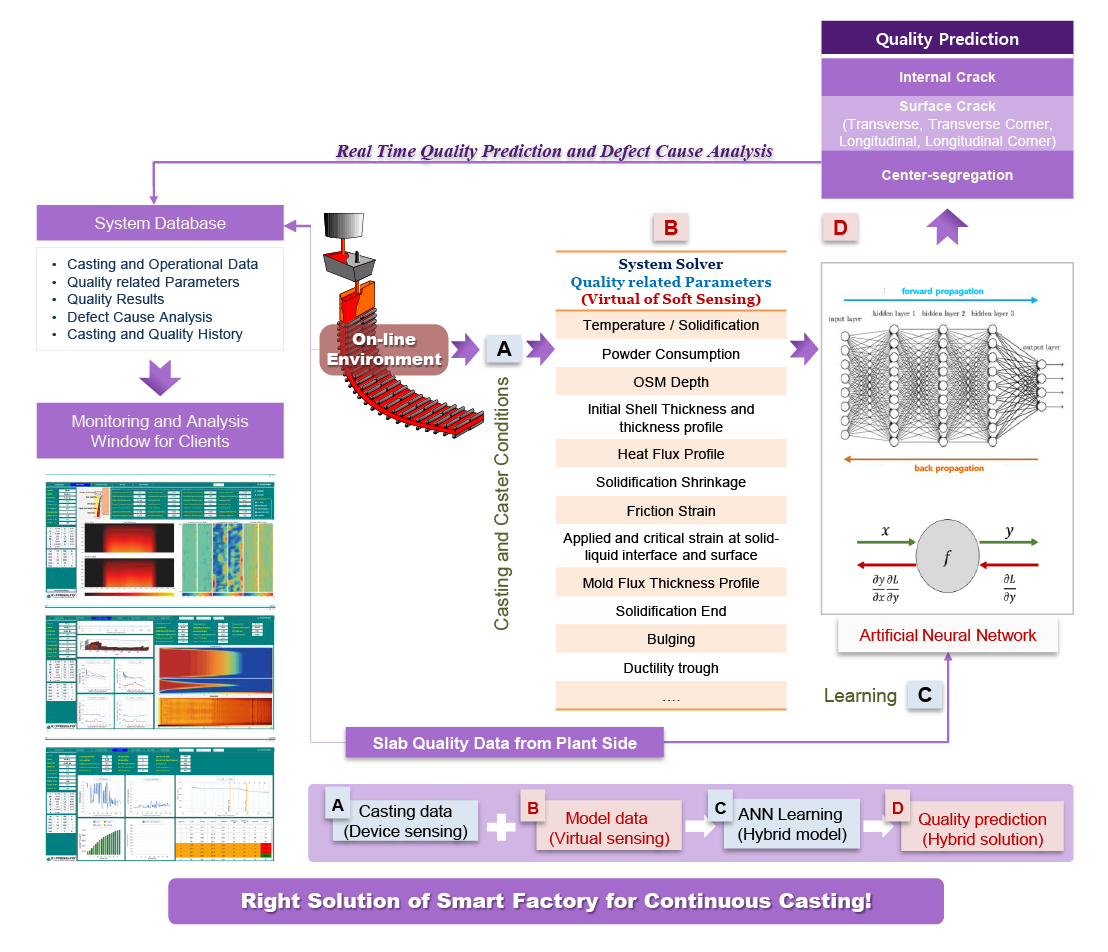

ANN(Artificial Neural Network) based Smart Factory System for Continuous Casting

CC-EYE offers a function of advanced on-line monitoring of quality related parameters, cracks, and central segregation during continuous casting. It may predict surface crack very accurately using the feature parameters from the system and artificial neural network. It also gives on-line prediction of the origins of defects and casting abnormalities, and it is easy to check whether these problems are solved. Eventually, the basic framework for Smart Factory System for continuous casting can be constructed.

On-line Prediction of Qualities and Origins of Defects

ANN based Expert System for Continuous Casting

Predicting Qualities by Artificial Neural Network Learning ModelReal time Check of Casting Conditions & Quality Index

Check History of Casting Conditions & Quality Index

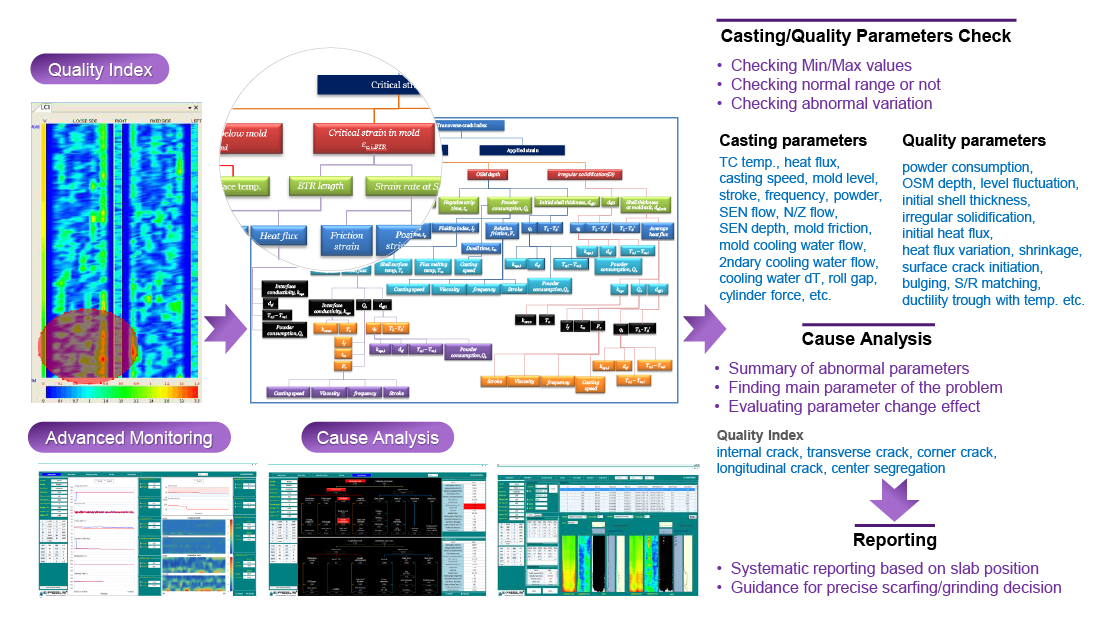

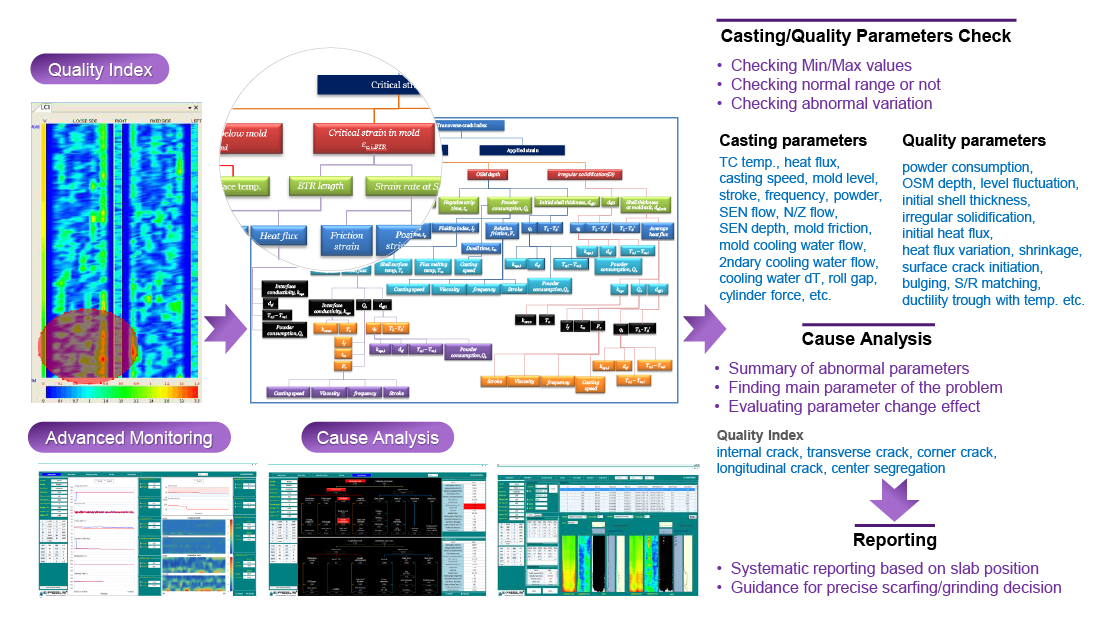

Scarfing/Grinding Decision Guide

Finding Cause of Defect and Solution Guide

Data Management of Casting Information and results

Cause Analysis & Reporting

Benefits

- basic platform for defect-free slab casting and highly efficient casting operation

Expected profit from minimizing the defect ratio of each steel grade

Reducing the required time for problem solving

Reducing the cost for trial and error by drawing optimum casting condition through carrying out off-line simulation before new steel grade production

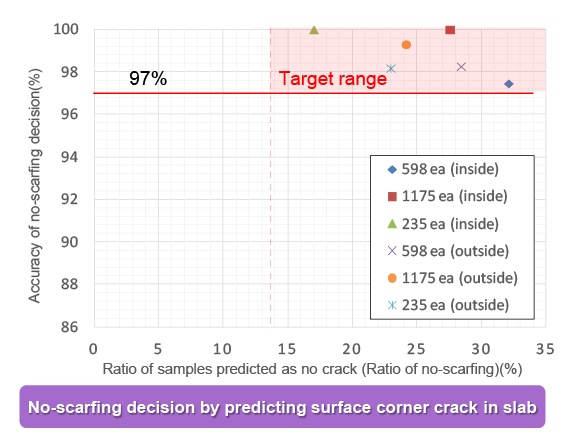

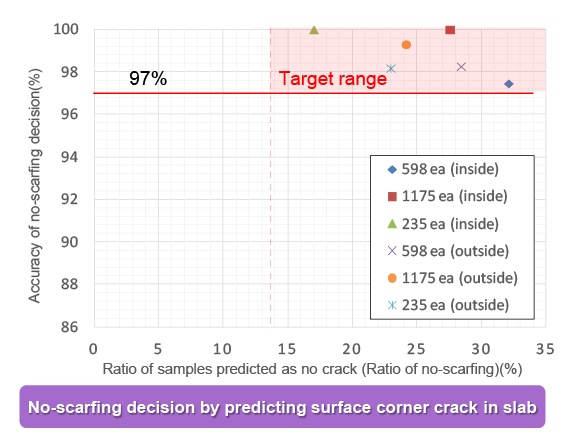

Reducing the cost of scarfing loss by predicting surface crack for precise scarfing decision

Requirements

Database S/W : Oracle or MS-SQL

Network : TCP/IP networking with Level2 and Level3 system

Client PC : Desktop or Notebook PC

Operating system : Windows Server (32/64 bit)

Can be changed by

- situation of inventories at ordering time

- user requirements

Advanced simulating

Software for Continuous Casting

CC-EYE

Catalog Download

Smart Factory System for Continuous Casting

CC-EYE offers function of an advanced on-line monitoring of quality related parameters, cracks, and central segregation during continuous casting. It also gives on-line prediction of the origins of defects and casting abnormalities, and it is easy to check whether these problems are solved. Eventually, the basic framework for Smart Factory System for continuous casting can be constructed.

On-line Prediction of Qualities and Origins of Defects

Expert System for Continuous Casting

Real time Check of Casting Conditions & Quality IndexCheck History of Casting Conditions & Quality Index

Estimation of internal crack considering mold and strand stages

Scarfing/Grinding Decision Guide

Finding Cause of Defect and Solution Guide

Data Management of Casting Information and results

Cause Analysis & Reporting

Benefits

- basic platform for defect-free slab casting and highly efficient casting operation

Expected profit from minimizing the defect ratio of each steel grade

Reducing the required time for problem solving

Reducing the cost for trial and error by drawing optimum casting condition through carrying out off-line simulation before new steel grade production

Reducing the cost of scarfing loss by predicting surface crack for precise scarfing decision

Requirements

System server : HP DL380 or higherDatabase S/W : Oracle or MS-SQL

Network : TCP/IP networking with Level2 and Level3 system

Client PC : Desktop or Notebook PC

Operating system : Windows Server (32/64 bit)

Can be changed by

- situation of inventories at ordering time

- user requirements